- Create a sand effect with a high level of roughness.

- A transparent, non-yellowing varnish with a satin coarse surface.

- For paper, cardboard, and plastics.

- Mesh 21 or 32 in screen printing is recommended

- An UV-curable varnish, which cures to a matte, fine-structured surface

- Excellent printability, leveling

- After curing, a clear, non-yellowing light-structured film is obtained

- Good flexibility

- A well-cured structure varnish (301.819V3) shows good abrasion resistance and is resistant to water and several solvents

- Good weather resistance

- Solids content: 100%

- Mostly used for decorative applications, the varnish can also be used for anti-slip floor stickers

- Mesh 43-62

- An UV curable varnish, which prevents the substrate slipping when applied to plastics and paper.

- Printing on the back of mouse pads. It prevents slipping and can also be used for any other anti-slip purpose.

- High Gloss

- Low odour

- Excellent printability, levelling, and flexibility.

- This product has a slight permanent tack after curing.

- Suitable for thick coating.

- Generally, weak adhesion is obtained in combination with the anti-slip effect.

- The printed anti-slip effect can be used repeatedly as long as the effect isn’t contaminated by dust.

- Coverage 10-30 m2 /kg

- Mesh 34-62

- UV curable varnish, which cures to a matte, light-structured surface with very high scratch resistance

- Mostly used for anti-slip floor stickers (matte surface)

- Excellent printability, leveling

- After curing, a clear, non-yellowing light-structured film is obtained

- Good flexibility, no curling or embrittlement will occur

- A well-cured anti-skid varnish (301.822) shows good abrasion resistance and is resistant to water and several solvents

- Good weather resistance

- Solids content: 100%

- 100% UV-curable.

- They have a matt soft velvet touch.

- For paper, PVC, polyester, coated PE & PP.

- A good adhesion on top of different inks.

- A deep matt aspect in any layer thickness.

- Screen 62- 120

- Excellent chemical and abrasion resistant.

- Accepts hot stamping.

- Needs higher UV doses because of its slow reactivity.

- For paper and plastics

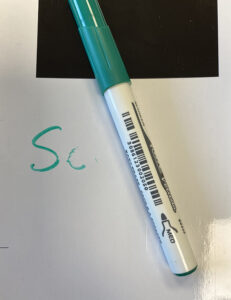

- UV varnish to produce a surface that can be written with dry erase markers and erased easily afterwards to reuse.

- Resistant to special markers that, once dry, can be erased.

- Polymerizing slowly or twice under the UV bulb will yield better results.

- Suitable for hard plastics such as PVC and PC and certain PS surfaces.

- High-speed curing at conventional UV curing systems

- High gloss, excellent leveling

- High surface hardness

- Excellent solvent resistance.

- High chemical resistance

- Suitable only for inside applications.

- Mesh 150-165

- UV curable varnish, suitable for non-coated and absorbing paper and board.

- Results in an equally glossy surface when printed on absorbing paper.

- Perfect as a primer or final layer.

- Mesh P 120 in screen printing is recommended.

- Anti Grafitti UV varnish

- Most inks and paint cannot adhere to the cured varnish.

- Solvent resistant

- High gloss

- mesh : 140 T- 180 S

- This varnish is used for security applications and for detection systems

- Luminescent effect (Under a „ultraviolet „Wood“ Lamp a bluish color appears.)

- High gloss, excellent leveling.

- Good surface hardness

- Good slip properties

- Highly flexible

- UV Release varnish.

- Ideal as primer for the rub removable UV inks

- Screen (165 T of 325/p in rotary screen) or flexo

- High gloss

- High reactivity.

- Sebuscreen foam varnishes 301.831 cures to a foam effect.

- Good adhesion to a wide variety of materials, like paper, board , PVC and PC.

- Excellent printability with stable foam reproduction.

- 4 % Hardener is recommanded to improve the scratch resistance of this foam structured surface

- A screen 43 – 90 is recommended.

- Sebuscreen foam varnishes 301.831 cures to a foam effect.

- Good adhesion to a wide variety of materials, like paper, board , PVC and PC.

- 301.831V1 results in more snake shaped bubble surface.

- Excellent printability with stable foam reproduction.

- 4 % Hardener is recommanded to improve the scratch resistance of this foam structured surface

- A screen 43 – 90 is recommended.

- Frost effect varnish for decorative applications (simulations of ice crystals on windows).

- Reactivity: 25 m/min. – 1 Lamp 120 W/cm.

- Screen mesh: P 90

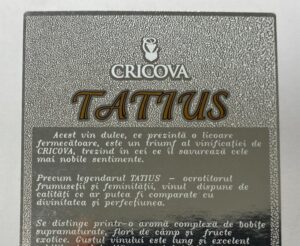

- Transparent matt baUV varnish

- The surface reacts to the metal in the coin and changes to dark grey

- Security or promotional application

- Screen: P150 – 165