Sebilac 410 is a serie of glossy phthalate free plastisol inks suitable for wet on wet printing.

- The Sebilac 410 inks are phthalate free.

- Low curing ink at 130°C

- Glossy aspect with a smooth soft hand.

- Suitable for T-shirts, sweatshirts and other woven cotton and cotton or polyester garments.

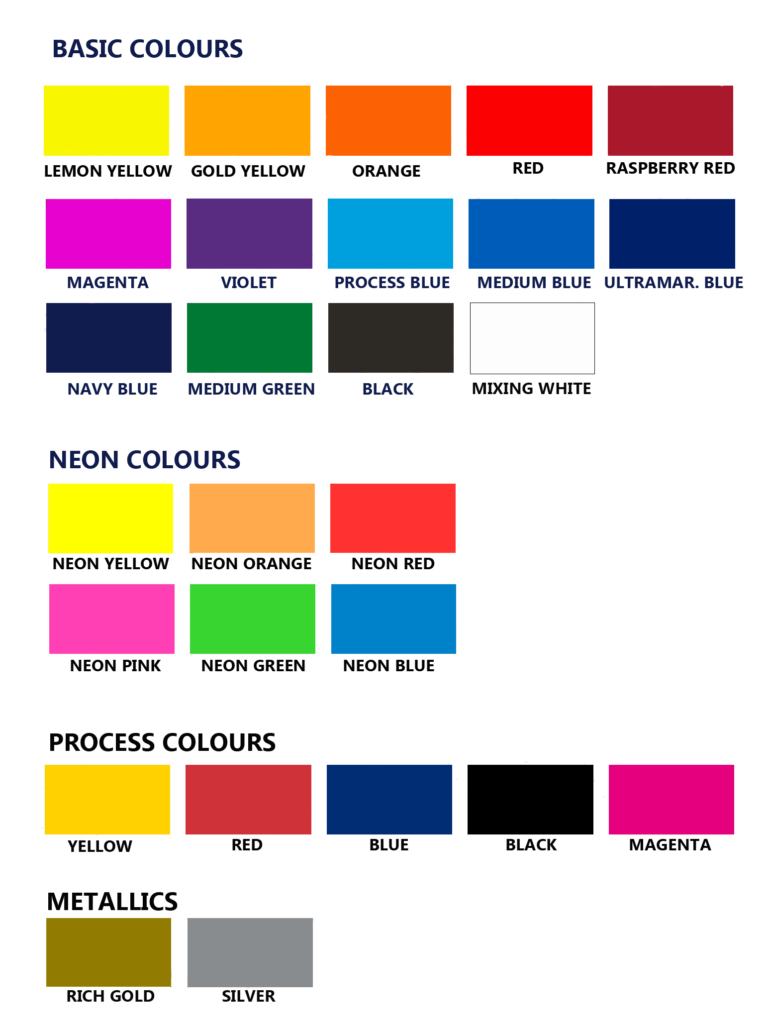

- Available in semi-opaque, opaque process, fluorescent and metallic colors.

- A full range of varnishes for special effects and to modify existing standard colors.

- Excellent release from the screen.

- The Sebilac inks allows wet-on-wet printing, without the use of intermediate flash lamps,

- All colors print well over a white underbase (410.751 or 410.753).

- Colour Matching System available

WHITE INKS

- Plastisol white, designed for printing opaque backgrounds with high whiteness and a soft, elastic feel.

- It dries quickly under flash lamps and offers excellent printability, even with high-mesh screens.

- Use as-is to maintain optimal drying speed and coverage.

- Suitable for use as a final white.

- Drying temperature: 150°C

- Plastisol white, ideal for printing opaque backgrounds with a soft, elastic feel and ultra-smooth surface to enhance overprinted colors.

- This white is perfect for elastic substrates like lycra, cotton jersey, and elastomer blends.

- It dries quickly under flash lamps, forming highly elastic films suitable as a final white or for transfer printing.

Drying temperature: 150°C

- Plastisol white, formulated for printing opaque backgrounds with a soft, elastic feel and ultra-smooth surface to enhance overprinted colors.

- It dries quickly under flash lamps and offers excellent printability, even with high-mesh screens.

- This special formula ensures full polymerization at 130°C, preserving the fabric’s original properties—ideal for materials sensitive to high temperatures that may otherwise experience color shifts or shrinkage.

- Suitable for use as a final white.

BASES

- Plastisol screen printing ink to be used as extender base for all products of the SEBILAC range.

- The product allows to reduce the intensity and covering power of colours without significantly varying their

viscosity, the brightness of the tones and the polymerization times.

Covering extender base, to be used with screens between 43 and 90

threads/cm. It is recommended to use this product to cut all the colours of the SEBILAC series, to reduce their viscosity without altering the opacity.

threads/cm. It is recommended to use this product to cut all the colours of the SEBILAC series, to reduce their viscosity without altering the opacity.

Screen printing plastisol base formulated to obtain glossy and very transparent, usable for glossy overprints that do not

yellow over time.

- Thanks to its high transparency it can also be used to print glitters, sequins.

- Suitable also for flock transfer process

- Plastisol ink designed for thick printing, characterized by a rounded shoulder, with a glossy and very transparent finish.

- Plastisol ink designed to create expanded 3D effects. The prints are characterized by high elasticity and a non-tacky (“non-sticky”) finish.

- Maximum mixing ratio: 30%.

- Plastisol ink formulated to be used as an additive for all products of the Sebilac series to obtain a matte

finish. - Mixing ratio: 20 – 40 %

- Screen printing plastisol transfer base usable up to 34 threads/cm.

- The transfer can be carried out with a hot press at a

temperature of 160°C for approximately 15 seconds.